TechTalk #17: Die Cutting Toolbox

Unfortunately, not every die runs without an issue. Every press operator has things that they do to get a die to run like they want it to. In order to do this, everyone needs a die tool box. The tools can be used alone or in conjunction with other ones to get the maximum life and run speeds out of the die.

Components of the Toolbox

Micrometer 0-1” or paper gauge

This is used to measure either the liner or the face thickness depending on what you are cutting to. It helps you to ensure that the material that you are cutting is what the die was manufactured for.

Foam

Depending on the surface area, depth of cut, and aggressiveness of the material, the only way to strip a shape is to hold it down while pulling away the matrix. This is done by packing the shapes with foam and stripping directly off of the die. You will need a foam of about .0625” thick for solid dies and .005” thick for flexible.

Stepped anvils

A set of stepped anvils can help you get deeper or lighter die strikes on a particular material They can also be used to extend die life on tools that have worn outside of the cutting range. We suggest a set of anvils where the bearer area is .0005” lower and .0005” higher than the area on the anvil that is used for cutting.

10x loop

This can be used to inspect the blades on a die for damage. Damage is the primary reason tools come back for retooling prematurely.

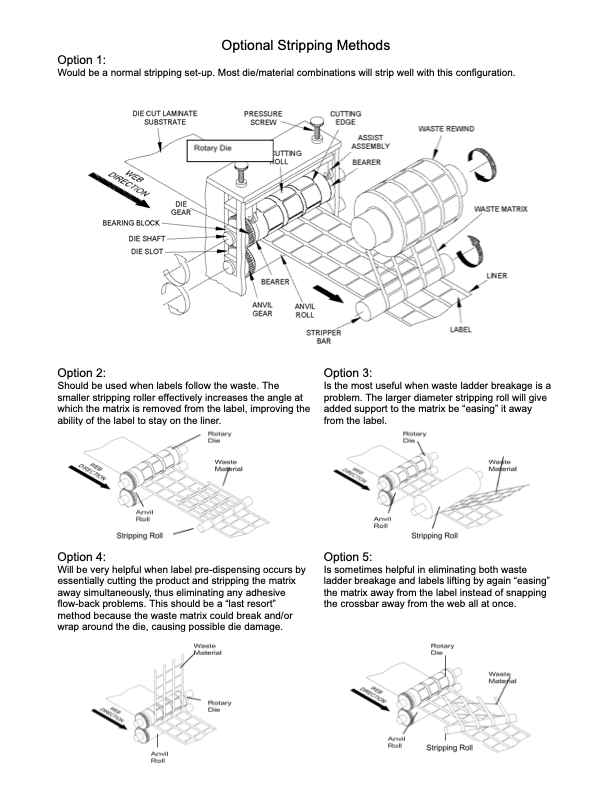

Stripping Chart

Use of a stripping chart, like the one below, at every press can remind the press operator to try different methods to get the tool to strip properly.

Implementing a die cutting toolbox will help you achieve the best results and be prepared to troubleshoot when issues occur. Contact us for more information.

Ready to get started on your next project?

We’re here to help. Whether you know all the details of your job or need a little guidance, our team of professionals is ready to get to work for you.